Patents

-Millenium® Arxe

-Monolithic

TECHNOLOGY

ARXE

Just like the Greek philosophers Arxe represents the origin, the generating principle of things (in greek ἀρχή, which means “principle”, “origin”), Millenium® Arxe constitutes the genesis of our sail loft.

A new name for a historic product, summary of the research and development in the construction of sails in a single piece, which the company has been a pioneer since the 80s. Hand in hand with boat construction, in fact, Millennium Technology Center revolutionized the sailing Italian market in 1983, patenting and introducing “Tape Drive” onto the regatta field, the first sail glued by continuous fiber Made in Italy (in a single piece).

A reference for technology, which was perfectionized in 2005 with the Millenium patent , which consents the construction of sails in a single piece that are one of a kind, without dimension limits and built through the die casting process.

Millenium® Arxe

The range reflects the ample selection of fiber used to make: taffeta, in various colors. The taffeta is pre-assembled to the other layers to enter in the cycle of die casting and become an integral part of the membrane. The men at Polo technological Millenium follow and optimize the production chain for the purchase of all the materials that make up our sails, and they are used exclusively after analysis and approval of the technical staff.

In the production process neither hot modeling or plastic deformation of the materials takes place and the fiber cables are laid out continuously from one angle of the sail to the other, making it light, strong and non-deformable.

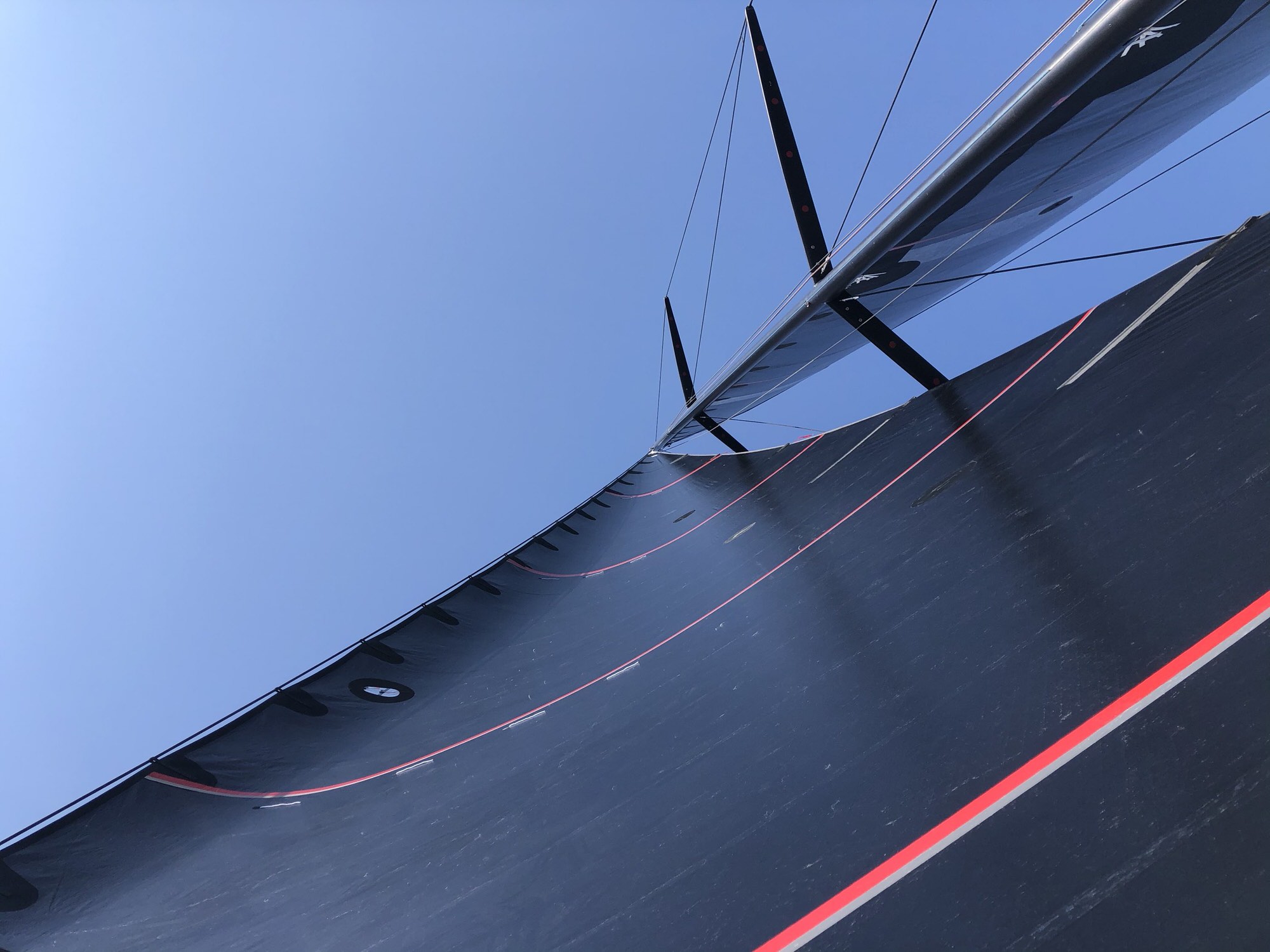

Millenium® Arxe doesn’t have dimension limits and holds the record for the biggest sails ever made in a single piece: The code#1 designed for the wally 143 “Esense”, with a length below 52 meters, and the mainsail of the J class “Shamrock”, of 462 square meters.

TECHNOLOGY

MONOLITHIC

What does Spead Fibers mean?

he whole sail construction is made up of very fine and almost invisible microfibre. The technique in spread fibers allows you to break down the carbon thread, PBO or Twaron operating on the microfibres of which it is composed, spreading them out. The microfibres are then reassembled in structural elements and arranged seamlessly in various layers and directions until they form the sail membrane. The result is a whole structure for the entire surface, with a rigidity like that of Carbon and the flexibility of a flag. In short, a completely compact sail without any fractures and divisions.

From this comes the name “Monolithic”, due to the fact that the membrane is resistant and every single fiber is anchored to the others, like a monolith.

This sail is free of inert and / or low modulus polymers such as taffeta and films. The use of molds also guarantees greater precision and perfection during lamination.

THE ADVANTAGES OF MONOLITHIC IN RESPECT TO OTHER SAILS IN SPREAD FIBERS

- For each sail a mold is used, generated with numerical control.

- The use of a two component adhesive that renders the sail invisible where other glue types do not, for example thermoplastic.

- Single piece sail with no joints: avoids different thicknesses on the surface that provoke breaking in the fibers in the overlapping zones.

- Fineness of the layers.